Lumber Grading, Lumber Characteristics, Defects, Softwood Knots

Simple knot commonly used for towing a log. To Step use Arrow Keys ( ). Set Speed using 1 - 5. Pass the end of the rope around the pole and then around the standing end. Wrap the end around itself three times and tighten the knot so that the three turns are gripped against the pole.

Four kinds of wood knots in the dataset (a) decayed knot, (b) encased... Download Scientific

A most commonly observed defect in timber are Knots.These occur where branches have grown out of the tree trunk. They are more common in some timbers (e.g. Pine) than others. 'Live Knots' are fully integrated with the surrounding timber.They may reduce strength and increase difficulty working the timber but are mainly a visual defect - indeed, Knotty Pine is used to decorative effect.

Lumber Grading, Lumber Characteristics, Defects, Softwood Knots

(v) Edge Knot: It is seen only in saw-on timber, on one edge of the cut portion. (vi) Face Knot: It is also seen on cut timber on the face of the board. Knots of whatever type and shape are always to be considered as defects in timber. They influence the quality of timber at least in two ways: Firstly, they make the workability of timber quite.

Wood Knots Free Stock Photo Public Domain Pictures

The dead timber inside the knot can be a fire hazard as it is very dry. Shakes. This defect occurs when there is internal stress within the timber and it causes cracks along its grain direction; this defect cannot be seen on the outside surface. It occurs when timbers start to split along their grain due to changes in moisture content or.

17 Essential Knots Every Survivalist Needs to Know ROFFS™

Knots: Knots are the most common defects caused due to natural forces. During the growth of a tree, branches close to the ground or lower branches die. Bases of those branches remain in the tree as the trees grow. These bases may create imperfection known as knots. Types of Knots: Knots are of two types.

What are Knots? Plant Science 4 U

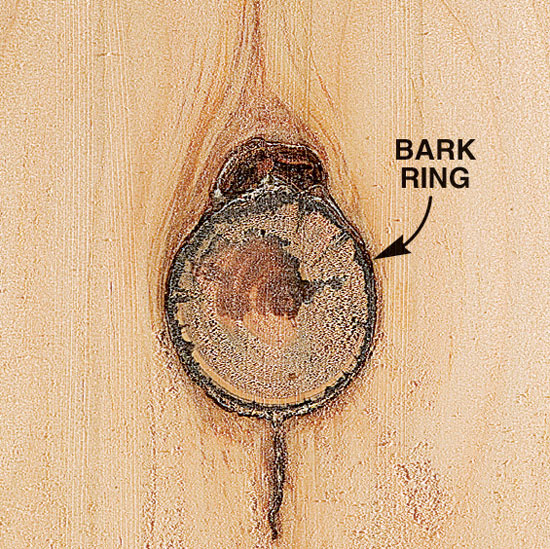

Woodworkers are quite familiar with these defects - knots, splits, ugly dark streaks or stains, worm holes, even decay. Some of the more common wood defects all woodworkers face include: Bark.

wood knot a photo on Flickriver

A knot near the edge can cause a sharp bend or "kink" in a board. The wood around a knot is under an incredible amount of stress caused by supporting the weight of a branch. The stress is balanced when the knot is in the middle of a board, and unbalanced when the knot is near the edge.

Knots Popular Woodworking

Knots are broken off/cut limbs or sprout branches that reveal exposed wood, either sound or rotten. In simple words, these are common blemishes in trees, which are known to often cause holes or lumps within the trunk of the tree in question. A knot on a tree trunk (Photo Credit: Pixabay) Also Read: What Happens When A Tree Is Struck By Lightning?

Knots in Wood? What's That? The Basic Woodworking

Knots are the spots of weaknesses in timber when used to carry compression. They are called nail knots when the diameter is less than 6 mm; it is called a small knot when it is 6 - 20 mm, it is called a medium knot when it is 20 - 40 mm, it is called a large knot when the diameter is more than 40 mm.

Knots Popular Woodworking Magazine

The effect of thermal modification (TM) on the chemistry, anatomy and mechanical properties of wood is often investigated using small clear samples. Little is known on the effect of growth-related and processing defects, such as knots and checks, on the bending strength and stiffness of thermally modified timber (TMT). Nine boards of Norway spruce with different combinations of knot types were.

Free Wood Knot Stock Photo

Knots are remnants of branches found in sawn timber and have widely been considered as defects for timber grading (Qu et al. 2019). First, knots cause deviations in the fiber direction and significantly reduce the mechanical properties, such as Young's modulus, shear modulus, etc. (Sarnaghi and Kuilen 2019).

Timber With Knot Free Stock Photo Public Domain Pictures

The derived and verified model of knot effects on sawn timber was applied to predict the severity of stress states for various knot positions in tensile loaded timber members. From these results a.

Lumber Grading, Lumber Characteristics, Defects, Softwood Knots

With respect to size, unsound knots are judged by the same rules as sound ones, but the rot cannot extend more than 3 inches (7.6 cm) into the included timber. In practice, this means that an unsound knot of acceptable size is a degrader if the rot extends into the log for a distance exceeding one-fifth of the log diameter.

Knots in Timber Timber, Types of timber, Building materials

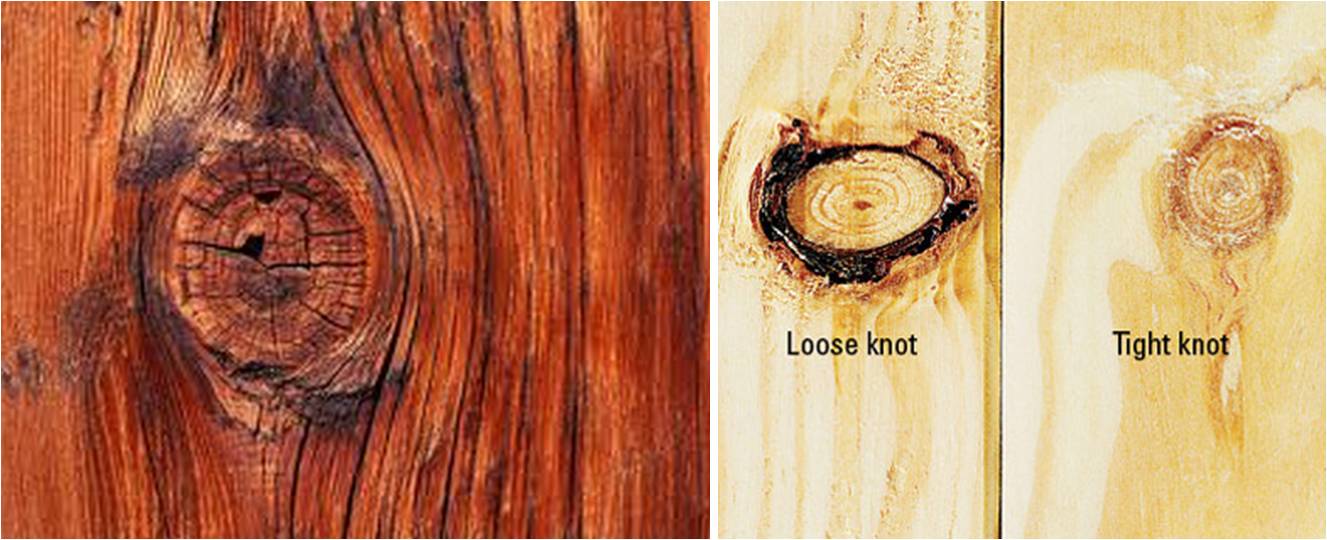

Knots occur in lumber when part of a branch is included within the wood of a piece of lumber. The size and shape of the knot contained within the lumber will depend on the size and orientation of the branch or branches to the cutting or sawing pattern of the log.

Lumber Grading, Lumber Characteristics, Defects, Softwood Knots

Loose knots are when the branch has died and is embedded in the tree. When this wood is cut for timber, the knot can easily fall out and leave a hole. It is these knots that reduce the strength of the wood. The other types of knots that you may find are called epicormic sprouts and are caused by excessive pruning.

Lumber Grading, Lumber Characteristics, Defects, Softwood Knots

Monday, 4 November 2019 3:43 pm Knots form during the growing process of a tree. A tree grows in two different directions. First, it grows in height. As the tree grows in height, limbs start to form off the sides. These limbs are the source of knots. The second direction of growth is in diameter.