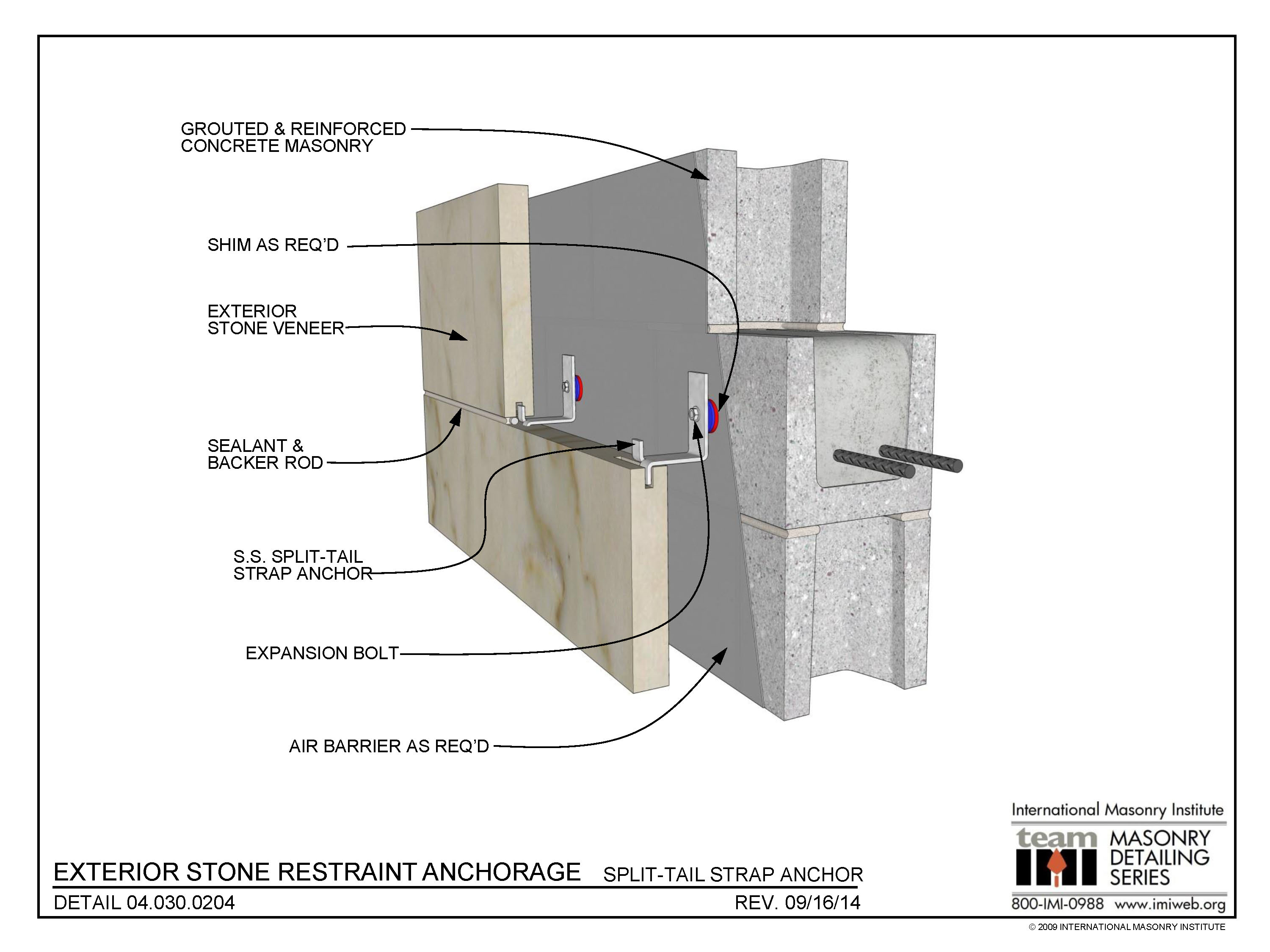

04.030.0204 Exterior Stone Restraint Anchorage International Masonry

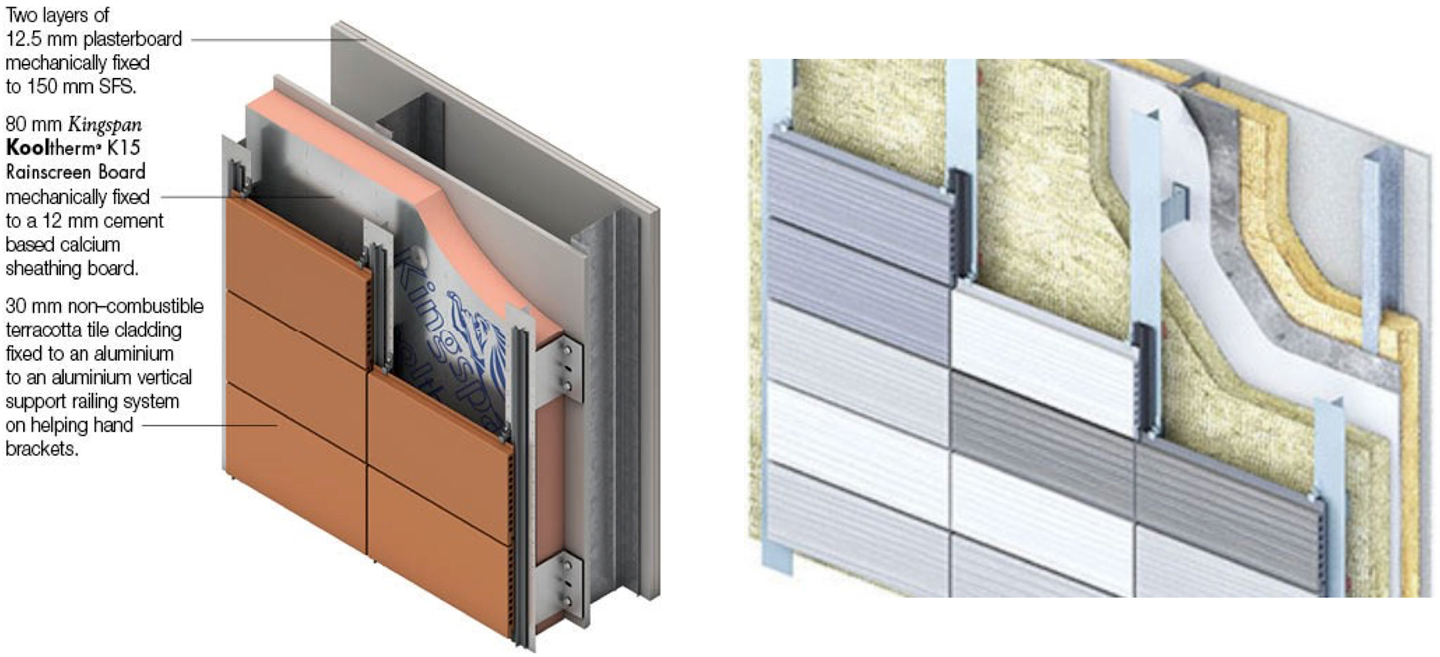

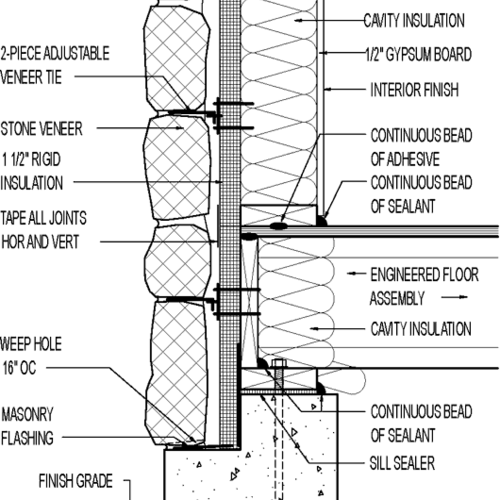

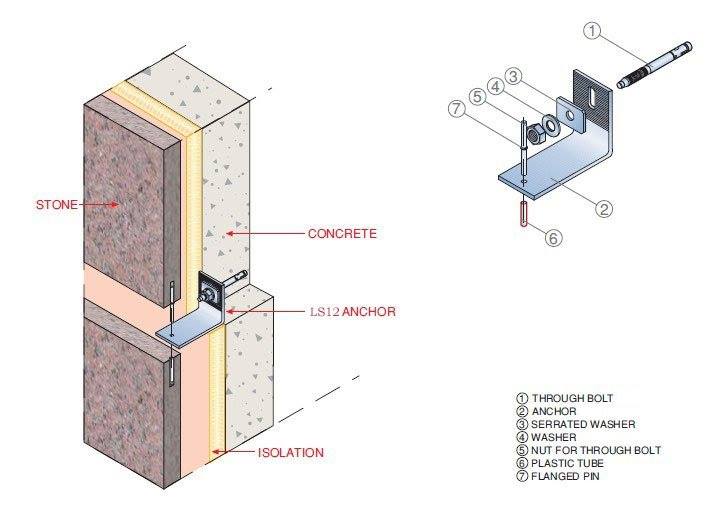

Dry Stone Mechanical Cladding System components vary depending on several factors such as: 1- Stone Weight. 2- Cavity Size. 3- Building Architectural design. 4- Concrete Slabs. The system can include metal framing, which consists mainly of steel C-Channels of various finishes, heavy duty anchors, steel brackets and bolts.

Stone Cladding and Details that are Hiding Behind the Beautiful Finish

Dry wall cladding or mechanical cladding is a type of cladding where two types of metals are mixed together to form a fusion welding. For example, marble and granite cladding is generally used for concrete walls, block work, masonry work etc. Now that we know what is dry cladding let us learn about the advantages and disadvantages of dry cladding.

Detail Post Cladding Details

According to Shameri [6], dryfixed stone cladding includes a cavity space between the facade layers, making it more attractive than standard skin facades because of the resulting acoustic and.

Stone Cladding and Details that are Hiding Behind the Beautiful Finish

138 CAD Drawings for Category: 04 42 00 - Exterior Stone Cladding Thousands of free, manufacturer specific CAD Drawings, Blocks and Details for download in multiple 2D and 3D formats organized by MasterFormat.

Dry Cladding, Rs 245/square feet Samor Cladding System Private Limited

ifications for Dry-Set Portland Cement Mortar ANSI A118.4 — American National Standards Institute Specifications for Modifed Dry-Set Cement Mortars ANSI A118.15 — American National Standards Institute Specifications for Improved Modified Dry-Set Cement Mortar TMS 402 — Building Code Requirements for Masonry Structures.

Stone Cladding and Details that are Hiding Behind the Beautiful Finish

Introduction to Cladding Details Cladding Details - Functional Requirements There are a wide variety of walling and cladding systems available for commercial and industrial structures, with many factors determining what construction method is chosen.

Cladding Systems For Steel Framed Buildings

Another useful way to categorize stone cladding is wet or dry. Wet cladding installation involves setting stone or stone panels in mortar directly on a substrate, while dry cladding panel installation secures the siding with a slip system.. Let's look at some of these characteristics in more detail. Strength of stone cladding. Samoli.

Dry cladding subframe and clips Nextec

In this article, we discuss the procedure for installing marble wall cladding that includes dressing, fixing, and joint making. Figure-1: Marble Wall Cladding. 1. Dressing of Marble. The dressing shall be same as specified except that the back shall not be dressed, but left rough cut, in order to ensure a good grip with the hearting or backing.

What is Stone Cladding AlterEgo Facades

Stone Panels, International. SP-16 - Interior Adhesive Attachment Over Gypsum Wallboard. SP-17 - Interior Structural Silicone Attachment Over Steel Stud Framing / Furring. Exterior Stone Cladding - Masonry - Download free CAD drawings, CAD blocks, AutoCAD drawings, & details for all building products in DWG & PDF formats.

Natural Stone Cladding Give Retro and Unique Look to Your Home!

Nevertheless, the durability of the dry-fixed cladding is highly dependent on the performance of the stone and the fixing details and, therefore is highly dependent on the adherence of the design and construction to the technical parameters of the cladding systems, such as anchors resistance, suitability between the stone and joints materials.

vynikat příkaz Hlučný dry stone cladding fixing detail Pokrýt Posun

16 Brick Cladding Constructive Details. Save this picture! Brick Veneer Wall. Image Cortesía de Endicott. Traditionally, bricks have been used in architecture to fulfill a double function.

How Metal Cladding Works, From Connection Details to Material Choices

Step-1: Calculate the Material Requirement Before starting with the installation procedure you first need to calculate the area where you want to clad. You can calculate by simply measuring its length and breadth and then multiplying it. This would help you get an estimated amount of material for the cladding. Step-2: Surface Preparation

Gallery of 16 Brick Cladding Constructive Details 1

CATALOGUE MECHANICAL CLADDING FIXATION 1 - About SFSP - General Information - Types of Load - Types of Fixings - L-Brackets - Z-Brackets - Case Study - Omega Bracket - Fishtail Bracket - Corrugated Dowel - Examples of Steel Back Support System - Locations INDEX Mechanical Cladding Fixation 4 20 26 34 47 59 64 72 75 78 82 90 www.sfsp-ikk.com 3

STONE CLADDING ASSEMBLY DETAIL Team M.B.C.C

Step 4: Installation of Wall Stone Cladding. Before starting the installation, always arrange the tiles and fix the design layout. Then follow the below steps: Clean the surface. Do not wet the surface before the cladding commences. Apply the mortar mix to a minimum bed thickness of 10mm. Apply mortar just required for a single piece.

an image of a section of a wall showing the details

"Dry-hang STONE cladding veneer TECHNICAL details." General. Both EcoSmart Stone and TechStone products are designed for fixing and installation using the patent pending SmartClip. Effectively a dryhang system. This allows a 20mm airspace between the frame and the wall cladding resulting in a cavity system.

Portfolio IQUBX

Insulation: Stone cladding can be easily coupled with thermal insulation products that are designed to reduce the heat loss or heat gain of a building envelope. The insulation should be non-combustible, rot and vermin proof and non-absorbent. In designing the insulation layer, strive for the lowest possible U-Value.